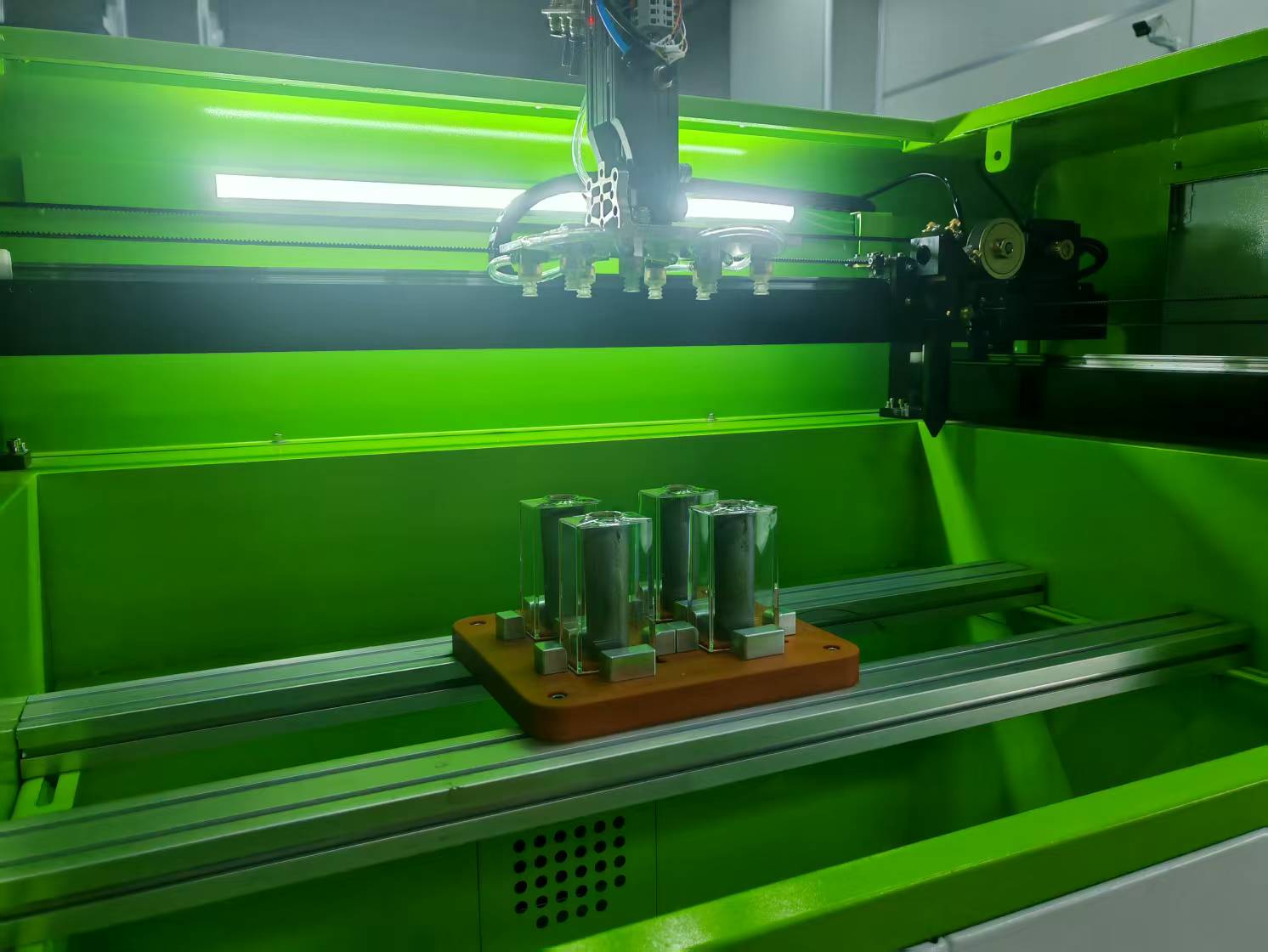

With the continuous development of the manufacturing industry, the requirements for product processing accuracy and efficiency are increasing day by day; (Laser cutting equipment was introduced in January 2025)

1.To improve production efficiency and reduce workers' labor intensity, we have introduced a laser gate cutting machine that uses high-energy laser beams for cutting. The cutting speed is extremely fast and can complete a large number of gate cutting operations in a short time. Compared with traditional manual cutting or mechanical cutting methods, the cutting speed can be increased several times;

2.The equipment has a high level of automation and can perform a series of operations such as automatic feeding, positioning, cutting, and discharging. Operators only need to perform simple parameter settings and start the equipment, and the machine can run automatically, reducing manual intervention and operating time;

3.The laser gate cutting machine uses the high-precision characteristics of the laser. It can accurately cut along the contour of the gate without causing any damage to the main body of the product, ensuring the integrity and appearance quality of the product;

4.High-precision cutting can also ensure the consistency of the gate residual height, avoiding the problem of uneven gate cutting by traditional manual methods that may affect product assembly or performance;

5.Due to the high cutting quality, the product pass rate is also correspondingly increased, reducing the scrap rate caused by quality issues and further lowering material costs;

19

2022-0919

2022-0919

2022-0919

2022-0919

2022-0919

2022-09